High-efficiency heat transfer is a critical requirement for HVAC, district cooling, and process industries across the UAE, optimizing energy use in a demanding climate. From commercial towers in Dubai to food processing plants in Sharjah, inefficient thermal systems drive up operational costs. Piranha Ecotech , a leading plate heat exchanger supplier in the UAE, offers high-performance plate and frame heat exchangers that provide superior efficiency in a compact footprint.

Our compact heat transfer solutions ensure precise temperature control and maximum energy recovery for all commercial and industrial applications. These systems are vital for supporting energy-efficient operations, enhancing both sustainability and cost savings nationwide and ensuring your facility achieves peak thermal performance across the Emirates.

Across Dubai, Abu Dhabi, Sharjah, and Ajman, the UAE’s focus on energy efficiency poses challenges for conventional thermal systems. Whether you manage a district cooling plant, a food and beverage facility, or a large commercial building, energy waste and large equipment footprints are major concerns. Installing a high-efficiency plate heat exchanger in the UAE is a critical step toward reducing energy consumption, saving space, and improving operational responsiveness in the Gulf’s dynamic market.

Piranha Ecotech plate and frame heat exchangers deliver superior thermal performance across a wide range of commercial and industrial sectors:

Act as highly efficient evaporators and condensers in chiller systems or as “breakers” to isolate different cooling loops in large-scale district cooling networks.

Provide gentle and precise heating and cooling for pasteurization, sterilization, and wort cooling in dairies, breweries, and juice production plants.

Offer instantaneous and efficient hot water generation for hotels, residential towers, and hospitals, eliminating the need for large storage tanks.

Deliver close-approach temperature control for liquid cooling loops, efficiently dissipating heat from servers and IT infrastructure.

Used for central cooling systems, lube oil cooling, and jacket water cooling, offering a compact and efficient solution for vessels with limited space.

Suitable for cooling and heating less aggressive chemicals, solvents, and process fluids where high efficiency and a small footprint are key.

Ensure precise temperature control in purified water (WFI) loops and other sanitary processes requiring high-purity, stainless steel construction.

Efficiently transfer heat from a boiler or solar system to heat swimming pools in residential complexes, hotels, and recreational facilities.

Capture and reuse waste heat from processes like air compressors or effluent streams, significantly improving a facility’s overall energy efficiency.

Discover the core advantages of compact, high-efficiency heat transfer solutions for the UAE’s demanding applications.

The corrugated plates create high turbulence even at low flow rates, resulting in extremely high heat transfer coefficients. This allows for closer temperature approaches, maximizing energy recovery and system efficiency.

Plate heat exchangers can provide the same thermal duty as a shell and tube unit in a footprint that is up to 80% smaller. This frees up valuable mechanical room space, a critical advantage in dense urban areas like Dubai.

The modular plate and frame design allows for easy expansion or modification of capacity. You can simply add or remove plates to adapt the unit to changing process needs, offering unmatched flexibility.

Due to their higher efficiency and smaller size, plate heat exchangers often have a lower initial purchase price and are less expensive to transport and install compared to shell and tube alternatives for the same duty.

The low fluid volume within the exchanger allows it to respond very quickly to changes in process conditions, providing tight temperature control that is essential for many sensitive applications.

The plate and frame design allows the unit to be fully disassembled for easy inspection, cleaning, and maintenance of all heat transfer surfaces, ensuring long-term high performance.

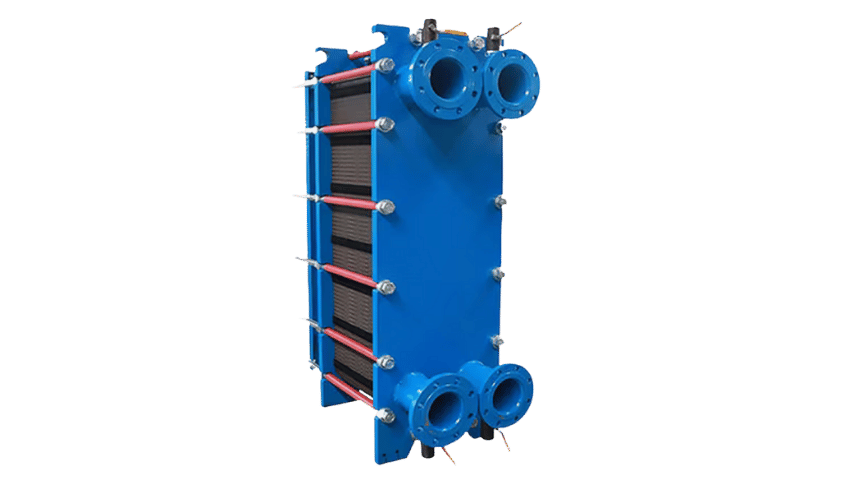

Piranha Ecotech provides a range of advanced plate heat exchangers engineered for the UAE’s diverse applications, each offering unique benefits for specific operational conditions:

This is the most flexible design, consisting of a series of plates held together in a frame with gaskets to seal the flow channels. It allows for easy disassembly for cleaning, maintenance, and capacity modification, making it ideal for HVAC, food processing, and general industrial duties.

Brazed plate exchangers consist of stainless steel plates that are brazed together with copper, eliminating the need for gaskets and a frame. This creates an extremely compact, durable, and leak-proof unit ideal for refrigeration, HVAC, and hydraulic oil cooling applications.

For applications involving high pressures, extreme temperatures, or aggressive fluids where gaskets would fail, welded plate heat exchangers offer maximum reliability. The plates are laser-welded together, providing the thermal efficiency of a plate design with the robustness to handle demanding chemical and refinery processes.

Choosing the correct plate heat exchanger for your facility in the UAE requires a careful analysis of your thermal duty, fluid characteristics, and operational environment.

Define the required heat load, flow rates, and desired inlet/outlet temperatures. The “temperature approach” (the difference between the hot fluid out and cold fluid in) is critical, as plate exchangers excel at achieving very close approaches (as low as 1°C), maximizing efficiency.

Identify the type of fluids, their viscosity, and whether they contain solids or fibers. This determines the required plate and gasket materials (e.g., Stainless Steel with NBR or EPDM gaskets) to ensure chemical compatibility and prevent corrosion or degradation.

The maximum operating pressures and temperatures of your system will determine the type of plate exchanger required. Gasketed units have specific limits, while brazed or welded designs are used for higher-pressure and higher-temperature applications.

Specify the maximum allowable pressure drop for each fluid circuit. Higher efficiency often comes with a higher pressure drop, so a balance must be found to optimize performance without overburdening system pumps and increasing energy costs.

Consider the need for regular cleaning. For fluids that can cause fouling, a gasketed plate and frame unit is ideal as it can be fully opened for mechanical cleaning. For clean fluid applications, a maintenance-free brazed unit may be more suitable.

Energy efficiency is paramount for profitable and sustainable operations across the UAE. Piranha Ecotech plate heat exchangers are designed to deliver maximum thermal performance for HVAC, district cooling, food processing, and data center facilities. Our advanced heat transfer solutions reduce energy consumption, save valuable plant room space, and provide precise temperature control. Trust Piranha Ecotech for high-efficiency thermal solutions and optimal performance across all Emirates.

Piranha Ecotech plate heat exchangers are engineered for the UAE’s efficiency-driven market and its diverse commercial and industrial humidity control needs.

The advanced corrugated plate patterns are designed to induce high turbulence, resulting in exceptional heat transfer rates. This allows for highly efficient energy transfer and enables a much more compact design compared to traditional heat exchangers.

We offer a wide selection of plate materials (Stainless Steel, Titanium) and gasket materials (NBR, EPDM, Viton) to perfectly match the chemical compatibility and temperature requirements of your specific application, from HVAC to food processing.

The plate and frame design allows for complete flexibility. Capacity can be easily increased or decreased by adding or removing plates, allowing the heat exchanger to adapt to your changing operational needs without requiring a full replacement.

Our plate heat exchangers offer a high-density heat transfer surface, providing a significant thermal capacity in a small and lightweight package. This simplifies transportation, installation, and saves critical plant room space in UAE facilities.

Gasketed plate and frame units are designed for serviceability. They can be opened quickly to allow full access to the heat transfer surfaces for inspection, cleaning, or plate replacement, ensuring minimal downtime and sustained performance.

Piranha Ecotech Electromechanical is a leading plate heat exchanger supplier in the UAE, offering advanced, high-efficiency solutions for the region’s commercial and industrial sectors. With nearly two decades of expertise, we specialize in supplying and installing high-performance plate and frame heat exchangers for diverse applications including HVAC, district cooling, food & beverage, marine, and data centers.

As a trusted name in UAE heat transfer solutions, Piranha Ecotech delivers reliable, compact, and customized systems to meet the specific energy efficiency goals of modern facilities. Our engineering team ensures every project meets stringent performance standards, delivering long-term savings and operational excellence.

Whether you’re designing a new energy-efficient building or upgrading an existing industrial process, choose Piranha Ecotech Electromechanical—the expert plate heat exchanger company in the UAE.

The main advantages are much higher thermal efficiency, a significantly more compact size, and greater flexibility to change capacity, making them ideal for many applications in the UAE.

Standard plate heat exchangers are best for clean fluids. However, for fluids with some particulates, we offer special “wide-gap” plate designs to reduce the risk of clogging.

Gasket life depends on the operating temperature, pressure, and fluid type. With proper operation, high-quality gaskets (like EPDM or NBR) can last for many years in typical HVAC and industrial applications.

Yes, if the frame is long enough. You can simply add more plates to increase the heat transfer surface area and boost the unit’s capacity, which is a major benefit.

Temperature approach is the difference between the outlet temperature of one fluid and the inlet temperature of the other. Plate heat exchangers can achieve a very close approach (e.g., 1°C), which signifies very high efficiency and maximum energy recovery.

Absolutely. We offer sanitary plate heat exchangers made with food-grade stainless steel plates and FDA-compliant gaskets, specifically designed for applications like pasteurization in the UAE food industry.

Maintenance typically involves periodic disassembly for inspection and cleaning of the plates to remove any fouling or scale. This process, known as Clean-In-Place (CIP) or manual cleaning, restores performance.

Yes, Piranha Ecotech supplies a full range, including gasketed plate and frame units for flexibility, and compact brazed plate heat exchangers for applications like refrigeration and OEM equipment.

We help you select the right material based on your fluids and temperatures. NBR is common for oil and fat applications, while EPDM is the standard for water, steam, and HVAC duties in the UAE.

Yes, we understand the critical nature of these units. We stock common sizes and can offer expedited replacement and installation services across Dubai and the wider UAE to minimize your downtime.

Designed & Delivered by Our Expert Team