Water-independent cooling is a strategic necessity for industrial facilities across the UAE, mitigating reliance on scarce water resources. From remote desert oil and gas sites to large-scale power plants near Dubai, water-based cooling systems present logistical and operational challenges. Piranha Ecotech , a leading air cooled heat exchanger supplier in the UAE, offers high-performance fin fan coolers engineered to provide reliable cooling using ambient air.

Our heavy-duty air-cooled solutions ensure consistent process temperature control without consuming a single drop of water. These fin fan coolers are vital for supporting critical operations in the energy and processing sectors, enhancing both sustainability and operational resilience nationwide and ensuring your facility can thrive even in the most water-scarce locations across the Emirates.

Across Dubai, Abu Dhabi, Sharjah, and Ajman, the UAE’s arid climate makes water a precious commodity. For industrial operations like refineries, power generation facilities, or gas processing plants, relying on water for cooling is often expensive, unsustainable, or impossible. Installing a high-performance air cooled heat exchanger (fin fan) in the UAE is a critical decision for ensuring operational continuity, eliminating water-related costs, and reducing environmental impact in the Gulf region.

Piranha Ecotech fin fan coolers provide robust and reliable water-free cooling across the UAE’s most demanding industrial sectors:

Cooling of hydrocarbon streams, overhead condensers for distillation columns, and process fluids in remote desert locations and large refineries.

Condensing exhaust steam from turbines (steam condensers), cooling closed-loop jacket water systems, and cooling auxiliary equipment.

Inter-cooling and after-cooling for gas compressors, as well as lean/rich amine cooling and gas dehydration processes.

Cooling various process liquids and condensing vapors where water is unavailable or its use is restricted.

Provide process cooling for steel mills, cement plants, and other large industrial facilities located away from a reliable water source.

Used in large-scale industrial HVAC systems or for cooling the inlet air for gas turbines to boost power output and efficiency.

Discover the core advantages of water-free cooling solutions for the UAE’s challenging industrial and environmental landscape.

The most significant benefit is the complete elimination of process water for cooling. This conserves a vital resource, cuts water utility costs, and removes reliance on municipal water supplies.

By eliminating water, you also eliminate the associated costs of chemical treatment, pumping, blowdown, and the maintenance required to combat scaling and corrosion in water-based systems.

Fin fan coolers allow industrial plants to be built in remote or arid locations where a sustainable water source is not available, providing immense strategic and logistical advantages in the UAE.

With no water consumption and no discharge of heated or chemically treated water (blowdown), air cooled heat exchangers have a significantly smaller environmental footprint than cooling towers.

Fin fan systems are simpler to operate than complex cooling tower and water treatment circuits. They remove the risks associated with handling water treatment chemicals and Legionella bacteria growth.

Designed and built according to robust standards like API 661, these units are engineered for high reliability and continuous operation in the extreme ambient temperatures common in the UAE.

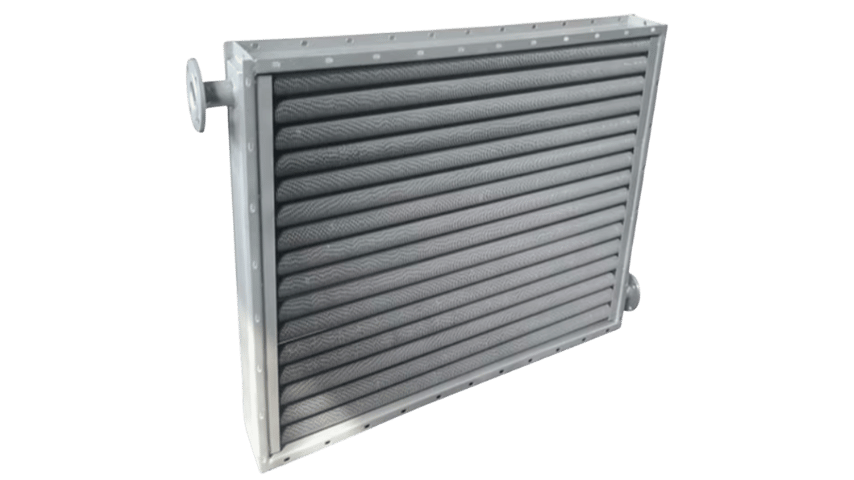

Piranha Ecotech provides robust fin fan cooler designs engineered for the UAE’s climate, primarily distinguished by their fan configuration:

In a forced draft design, the fans are located below the tube bundles and push ambient air upwards across the fins. This configuration offers easier access to the fans and motors for maintenance, provides better air distribution, and is the most common design for process cooling applications.

In an induced draft design, the fans are located above the tube bundles and pull air upwards through the fins. This design offers better protection for the tube bundles from weather, results in a more even air distribution, and ensures a higher exit air velocity, preventing hot air recirculation.

Water conservation is critical for sustainable industrial growth in the UAE. Piranha Ecotech air cooled heat exchangers are purpose-built for refineries, power plants, and gas compression stations operating in the extreme Gulf climate. Our API 661-compliant fin fan systems provide reliable process cooling, eliminate water consumption, and reduce operational expenditure. Trust Piranha Ecotech for robust, water-free cooling solutions and optimal performance across all Emirates.

Water conservation is critical for sustainable industrial growth in the UAE. Piranha Ecotech air cooled heat exchangers are purpose-built for refineries, power plants, and gas compression stations operating in the extreme Gulf climate. Our API 661-compliant fin fan systems provide reliable process cooling, eliminate water consumption, and reduce operational expenditure. Trust Piranha Ecotech for robust, water-free cooling solutions and optimal performance across all Emirates.

Piranha Ecotech fin fan coolers are meticulously engineered for the UAE’s demanding industrial climate and the need for water-independent cooling solutions.

Our units are designed to dissipate massive heat loads, making them ideal for cooling entire process streams in large-scale facilities like refineries and power stations. They provide reliable temperature control for critical equipment and processes across the UAE.

Engineered in compliance with API Standard 661, our fin fan coolers are built for maximum safety and reliability in demanding hydrocarbon service. This includes robust header box designs, high-quality welding, and durable structural supports.

We utilize various types of high-performance finned tubes (e.g., L-fin, embedded, extruded) to create a massive surface area for heat transfer. This ensures maximum cooling efficiency and a more compact design for a given thermal duty.

For facilities with strict noise regulations, we offer specialized low-noise fan blades and Variable Frequency Drives (VFDs). VFDs also provide significant energy savings by allowing fan speed to be optimized based on cooling needs.

For applications that require protection from cooler winter temperatures or precise outlet temperature control, we can incorporate features like louvers, steam coils, and hot air recirculation systems to ensure year-round operational stability.

Piranha Ecotech Electromechanical is a leading air cooled heat exchanger supplier in the UAE, delivering robust water-free cooling solutions for the region’s core industries. With nearly two decades of expertise, we specialize in the design, supply, and installation of high-performance fin fan coolers for oil & gas, power generation, and petrochemical sectors.

As a trusted name in UAE industrial cooling solutions, Piranha Ecotech provides reliable, API 661-compliant, and customized systems to solve the challenges of operating in an arid climate. Our engineering team ensures every project is optimized for high ambient temperatures, delivering long-term performance and sustainability.

Whether you’re developing a new industrial site or seeking to eliminate water dependency, choose Piranha Ecotech Electromechanical—the expert fin fan cooler company in the UAE.

They are highly effective because they are specifically designed for it. We use the highest expected summer ambient temperature as the design basis to ensure the unit will always meet the required cooling duty.

In a forced draft, fans push air across the tubes (easier fan maintenance). In an induced draft, fans pull air through the tubes (better protection from weather and less hot air recirculation).

Yes, compliance with API Standard 661 is a core offering for our clients in the oil and gas and petrochemical industries, ensuring the highest level of safety and reliability.

Yes. For precise temperature control, we can equip the units with Variable Frequency Drives (VFDs) on the fan motors, or with automated louvers that control airflow.

They require a significant plot area compared to other cooling systems. The exact size depends on the heat load and the design ambient temperature. We provide detailed layout drawings during the engineering phase.

Maintenance is relatively simple and includes periodic inspection and lubrication of fan motors and bearings, and cleaning of the finned surfaces to remove dust and debris that can hinder airflow.

The large fans can generate considerable noise. We can offer low-noise fans and other sound attenuation solutions to meet specific site noise level requirements (dBA at 1 meter).

To combat salt-air corrosion in coastal zones like Jebel Ali or Ruwais, we often recommend galvanized steel structures and can use specialized materials for tubes and headers to ensure a long service life.

Yes, we can design the tube side of the exchanger to handle viscous fluids by optimizing the tube diameter and number of passes to ensure proper flow while achieving the required cooling.

Absolutely. Piranha Ecotech offers a complete turnkey solution, from design and supply to full installation, commissioning, and after-sales support across all seven Emirates.

Designed & Delivered by Our Expert Team