Extreme process reliability is non-negotiable for the chemical, oil and gas, and heavy industrial sectors across the UAE, where leaks can be catastrophic. For applications with aggressive media, high pressures, or extreme temperatures in Jebel Ali, Dubai or Ruwais, traditional gasketed exchangers are a point of failure. PiraPiranha Ecotech nhaecotech, a leading welded plate heat exchanger supplier in the UAE, provides heavy-duty solutions engineered for ultimate safety and performance.

Our robust welded heat transfer solutions ensure absolute process containment and efficient thermal control for the most hazardous duties. These systems are vital for supporting critical operations where gasket failure is not an option, maximizing both safety and uptime nationwide and ensuring your facility operates with uncompromising reliability across the Emirates.

Across Dubai, Abu Dhabi, and Sharjah, demanding industrial processes in sectors like petrochemicals, refining, and specialty chemicals push the limits of conventional equipment. When dealing with corrosive chemicals, toxic fluids, or high-pressure steam, the risk of gasket leakage is unacceptable. Installing a heavy-duty welded plate heat exchanger in the UAE is the definitive solution for ensuring process integrity, protecting personnel, and eliminating the risks associated with gasketed designs.

Piranha Ecotech welded plate heat exchangers provide secure and efficient thermal control for the most challenging industrial duties:

Heating and cooling of aggressive acids, caustics, solvents, and other corrosive fluids where gaskets would rapidly degrade.

Used in duties with high temperatures and pressures, such as amine treating, hydrocarbon processing, and heat recovery from hot effluent streams.

Serve as highly efficient and safe evaporators and condensers in large industrial refrigeration systems that use ammonia (NH3) as a refrigerant.

Provide reliable thermal control for processes involving pure or aggressive chemicals where product purity and containment are paramount.

Used as utility heaters and coolers in demanding services, such as closed-loop cooling water systems or lube oil coolers in high-temperature environments.

Heating and cooling of acidic leaching solutions and other corrosive slurries found in mineral extraction and processing operations.

Discover the core advantages of gasket-free, robust heat transfer for critical and hazardous applications.

The fully welded design of the plate pack completely eliminates the risk of external leakage associated with gaskets, providing maximum safety and environmental protection when handling hazardous fluids.

By removing gaskets, welded plate heat exchangers can operate at much higher pressures and temperatures than traditional plate exchangers, bringing high efficiency to demanding duties previously reserved for shell and tube units.

The all-welded stainless steel or special alloy construction provides excellent resistance to a wide range of corrosive chemicals, acids, and solvents that would destroy conventional gaskets.

Welded plate exchangers retain the high thermal efficiency and compact footprint of plate technology, offering significant space and energy savings compared to bulky shell and tube units for the same duty.

The gasket-free design eliminates the significant cost and downtime associated with the regular inspection and replacement of expensive gaskets, drastically reducing the unit’s total cost of ownership.

The robust, all-welded construction is highly resistant to pressure and temperature cycling, providing exceptional mechanical strength and long-term reliability in the most demanding industrial applications in the UAE.

Piranha Ecotech provides robust welded heat exchanger designs, each engineered for specific high-stakes industrial environments in the UAE:

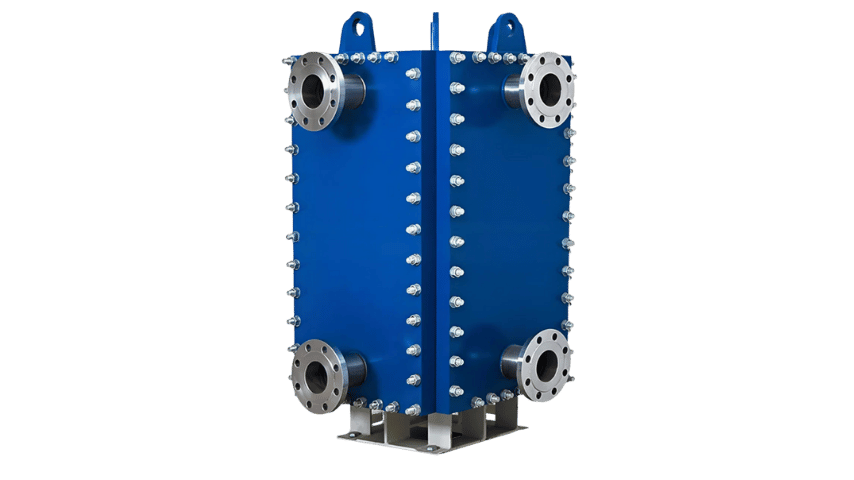

In this design, corrugated plates are welded together to form a secure, inseparable plate pack. This offers the thermal efficiency of plate technology with the robustness of a fully welded vessel, ideal for handling aggressive or hazardous fluids at high pressures and temperatures.

This hybrid design features a welded circular plate pack installed inside a traditional cylindrical shell. It combines the high efficiency and compact size of plate technology with the high-pressure capabilities and connection flexibility of a shell and tube exchanger, offering the best of both worlds for many refinery and chemical applications.

Choosing the correct welded plate heat exchanger requires a thorough risk and process assessment for your critical application in the UAE.

The single most important factor is the chemical composition of the process fluids. This dictates the required material for the plates and welds (e.g., 316L Stainless Steel, Titanium, SMO 254, Hastelloy) to ensure complete corrosion resistance.

You must specify the maximum design pressure and temperature the unit will ever be subjected to. This is critical for the mechanical design calculations to ensure the unit is robust, safe, and compliant with pressure vessel codes like ASME.

Define the required heat duty, flow rates, and temperatures. This allows for the thermal sizing of the unit, determining the required number of plates and surface area to meet your process needs efficiently.

While highly efficient, the channels are still relatively narrow. The fouling potential of the fluids must be assessed to ensure the design can operate for extended periods without requiring cleaning, which is more complex than with gasketed units.

The size, type, and orientation of the process connections must be specified to ensure the heat exchanger can be seamlessly integrated into your plant’s piping layout. This is especially important for Plate and Shell designs.

For critical process applications in the UAE, safety and reliability are paramount. Piranha Ecotech welded plate heat exchangers are the definitive solution for handling aggressive fluids, high pressures, and extreme temperatures where gasket failure is not an option. Our heavy-duty welded units provide the efficiency of plate technology with the security of a welded pressure vessel, safeguarding your operations in the chemical, oil & gas, and heavy industrial sectors. Trust Piranha Ecotech for ultimate process containment and reliable performance across all Emirates.

Piranha Ecotech welded plate heat exchangers are engineered for ultimate reliability in the UAE’s most critical and hazardous industrial processes.

Our exchangers feature a plate pack where the plates are laser-welded together at the perimeter. This creates a robust, hermetically sealed unit that completely prevents any possibility of external leakage, ensuring maximum process safety.

We construct our units from a range of high-performance materials, including 316L Stainless Steel, Titanium, and SMO 254, to provide superior corrosion resistance against a wide spectrum of aggressive chemicals, acids, and chlorides.

Engineered to operate reliably at pressures and temperatures that would cause instant failure in gasketed designs, our welded units bring high thermal efficiency to services traditionally handled by bulky shell and tube exchangers.

For ultimate versatility, our Plate and Shell models combine a welded plate core within a robust shell. This hybrid design handles extreme pressures and allows for flexible nozzle configurations while maintaining the high efficiency of plate technology.

Despite their robust construction, our welded plate exchangers maintain the key advantages of plate technology: high heat transfer coefficients and a compact footprint, saving valuable space and energy in your plant.

Piranha Ecotech Electromechanical is a specialist welded plate heat exchanger supplier in the UAE, providing ultimate thermal solutions for hazardous and high-pressure applications. With nearly two decades of expertise, we supply heavy-duty welded and plate-and-shell heat exchangers to the region’s most demanding sectors, including chemical processing, oil and gas, and industrial refrigeration.

As a trusted name in UAE critical process solutions, Piranha Ecotech delivers safe, reliable, and efficient systems that eliminate the risks of gasket failure. Our engineering team works closely with clients to select the correct materials and design for their most challenging thermal duties.

When process containment is critical and conditions are extreme, choose Piranha Ecotech Electromechanical—the expert welded heat exchanger company in the UAE.

Choose a welded unit when your application involves aggressive fluids that would attack gaskets, or when operating pressures and temperatures exceed the limits of a gasketed design. It’s a choice for safety and reliability.

Yes, but only through chemical cleaning (Clean-In-Place, or CIP). It cannot be opened for mechanical cleaning, so it is best suited for fluids with low fouling potential.

This varies by design, but our welded plate heat exchangers can be designed to handle pressures up to 100 bar (1,450 psi) and even higher, depending on the model and application.

Absolutely. The all-welded stainless steel construction is perfectly compatible with ammonia (NH3) and eliminates the risk of gasket leaks, making them an ideal and safe choice for industrial refrigeration in the UAE.

A fully welded unit has a rectangular plate pack and is more compact. A plate-and-shell has a circular plate pack inside a pressure vessel shell, offering higher pressure ratings and more nozzle flexibility, similar to a shell and tube.

We offer a wide range of materials, including stainless steel (316L), Titanium for chloride environments (like wet chlorine), and superior alloys like SMO 254 and Hastelloy for highly aggressive acids.

Yes, they utilize the same high-efficiency plate technology, offering superior heat transfer rates and a compact footprint compared to shell and tube exchangers of the same capacity.

Our welded plate heat exchangers are designed and manufactured in accordance with international pressure vessel codes such as ASME Section VIII, Div. 1 and the Pressure Equipment Directive (PED).

Due to the critical nature of these units, we require a detailed process data sheet, including fluid compositions, pressures, temperatures, and flow rates to provide an accurate and safe design proposal.

Yes. Our engineering team provides expert consultation to analyze your process conditions and recommend the optimal welded heat exchanger design and material selection for your application in the UAE.

Designed & Delivered by Our Expert Team